Archwires

- Unloading (springback) properties facilitate fast, efficient tooth movement.

- Due to the lower hysteresis of Copper Ni-Ti, the loading forces are smaller than their nickel titanium counterparts, making wire engagement in the bracket slot easier.

- A unique unloading profile provides continuous forces, even at very small deflections.

- More resistant to permanent deformation than other nickel-titanium wires.

- Batch-to-batch consistency, with a very precise temperature range, ensures true heat activation and consistent, predictable results.

- Easy to engage, even in the most severe cases.

Copper Ni-Ti wires

Copper Ni-Ti wires consist of nickel, titanium, copper and chromium.

The addition of copper to the alloy enhances the thermal-reactive properties of the wire. Ormco offers four different Copper Ni-Ti series: Damon Copper Ni-Ti and 27°C, 35°C, and 40°C Copper Ni-Ti. The higher the temperature transition (TTR), the lower the relative forces delivered by the wire. The Copper Ni-Ti series provides a wide range of options in selecting and delivering the force of choice and the wire size for the dictates of the case and treatment modality.

- Unloading (springback) properties facilitate fast, efficient tooth movement.

- Due to the lower hysteresis of Copper Ni-Ti, the loading forces are smaller than their nickel titanium counterparts, making wire engagement in the bracket slot easier.

- A unique unloading profile provides continuous forces, even at very small deflections (Fig. A).

- More resistant to permanent deformation than other nickel-titanium wires.

- Batch-to-batch consistency, with a very precise temperature range, ensures true heat activation and consistent, predictable results (Fig. B)..

- Easy to engage, even in the most severe cases.

Damon Copper Ni-Ti

Specifically calibrated for use with the Damon System. Additionally, the surface finish of the wires is smoother to maximize sliding characteristics.

27°C Copper Ni-Ti

Has a higher relative stiffness than 35°C or 40°C Copper Ni-Ti. As such, clinicians have found it to perform well in round cross-sections or when higher forces or stiffness are desired in rectangular cross-sections.

35°C Copper Ni-Ti

With its TTR close-to-mouth temperature, is soft at room temperature to facilitate engagement. It falls within a very efficient force range when used in the larger round or all rectangular sizes.

40°C Copper Ni-Ti

Delivers the lowest relative force of all nickel-titanium archwires. For initial alignment, it is best used in the larger rectangular sizes. As such, it may be indicated in very severe cases or in periodontally compromised patients.

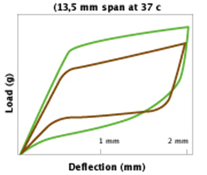

Comparing Loading/Unloading

Fig. A – Initial deflection force is lower with Copper Ni-Ti, making it easier to engage severely malposed teeth. As the wire springs back, more-consistent forces are maintained, even in minor deflections.

Transformation Temperature with Standard Deviations

Fig. B – Most so-called heat-activated wires have wide manufacturing tolerances, forcing their transformations to be set near room temperature. Thus they are fully active well before insertion in the mouth. The precision of Copper Ni-Ti allows the wire to be easily engaged before full activation at body temperature, thus true heat activation.

Tru-Arch Arch Form

The functional arch form must have the proper shape for optimal overcorrection. From a functional occlusion standpoint, the arch form should accommodate joint-dictated movement patterns. This means that both Tru-Arch forms are more broad and flat across the incisors. Additionally, the Straight-Wire® Appliance makes it possible to eliminate in/out archwire bends because the bracket thickness is engineered for the different tooth types. The customized bracket thickness also enables the bracket slots to accept the Tru-Arch shape without wire bends. Therefore, the Tru-Arch shape is the optimum shape for ideal occlusion with the Straight-Wire system.

TMA

Space Closure in the Age of “Variable Modulus” Mechanics

Ormco helped develop the original Beta Titanium wire more than two decades ago. Over the years, Ormco refined the TMA manufacturing process to a science in order to deliver the largest number of sizes and options available. Today, the TMA brand of Beta Titanium remains the industry standard for consistency and quality.

With half the force but twice the working range of stainless steel, TMA has indications for all stages of treatment. Because of its intermediate stiffness between stainless steel and the nickel-titanium memory alloys, it is especially beneficial as a main working archwire. TMA has good flexibility and springback characteristics along with predictable forces for consistent control.

- Initial Stage – TMA is recommended for tooth alignment, space closure and curve of Spee. Ormco offers preformed Reverse Curve TMA and Reverse Curve TMA with “T” Loops.

- Intermediate Stage – TMA is recommended for early torque control with moderate forces. TMA also provides complete manipulation of the wire for dimensional control. Indications include use as an ideal retraction arch while exerting more-constant moderate forces over a longer period of time.

- Final Stage – TMA is used as a detailing wire with moderate force.

Low-Friction and Colored TMA®

If sliding mechanics and minimum friction are your goals, then you will appreciate the benefits of Low-Friction and Colored Low-Friction TMA. TMA colors also offer patients exciting new looks.

Ni-Ti

Ormco’s trademark nickel-titanium wire, Ni-Ti has the resiliency and high springback necessary during treatment. Ni-Ti is indicated for initial leveling, aligning and rotational control.

Turbo Wire

Turbo Wire is a nine-strand rectangular braided Ni-Ti, with low stiffness and great flexibility. Turbo Wire is recommended as an initial wire to unravel and level while controlling torque and engaging brackets fully. It is also effective as a finishing wire, retaining torque but allowing vertical elastic use.

Titanium Niobium FA (Finishing Archwire)

Titanium Niobium FA is an innovative archwire designed for precision tooth-to-tooth finishing. The unique metallurgical properties of Titanium Niobium FA make it a precision intraoral detailing option. At 80% of the stiffness of TMA, it is perfect for holding bends, yet light enough not to override the arch-to-arch relationship. It is recommended for use with finishing elastics and even though it feels soft and pliable, it possesses a resiliency after bending that is equal to stainless steel.

Stainless Steel

Ormco stainless steel wires are made of 300 series alloys to high tensile strengths in excess of 300,000 psi. The wires are manufactured to the highest quality for dimensional precision and surface finish, providing optimum forces for arch stability, resilience, formability and sliding mechanics.

D-Rect

D-Rect is an eight-strand braided stainless steel wire. It can be used throughout treatment where lighter forces with dimensional control are indicated.

Triple Flex

Triple Flex is a three-strand twisted stainless steel wire. It has moderately light forces and is used for initial leveling and alignment.

Respond

Respond is a stainless steel coaxial wire. It is recommended as an initial archwire to level and align because of its light, gentle forces. Respond is also very flexible and possesses great springback characteristics. One of the benefits of Respond includes great control with larger initial wire diameters.